What is EP Coating?

Electrophoretic coating or EP Coating is a painting process which is used to coat a wide range of metal components to enhance resistance to corrosion.

How Do We Apply EP Coating?

Rudd Macnamara provide EP coated metal parts. With EP coating the substrate is immersed in a bath of paint. An electric current is then used to attract the particles that are suspended in the liquid solution and deposit them onto the surface of the substrate.

The electrodeposition continues until the desired level of coating thickness is achieved, which can be precisely regulated by increasing or decreasing the voltage level for a uniform coating. The coated substrate is then cured in an oven to promote cross-linking.

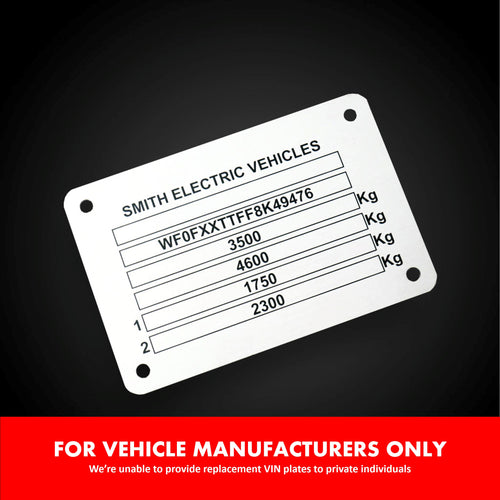

Benefits of EP Coated Nameplates

Rudd Macnamara offer EP coated nameplates that provide excellent properties:

- Precisely control the thickness of coating across the entire part

- Extremely cost effective

- Can be used as an excellent primer as well

Contact Us

For further information on our range of processes please click on the links below or call us on +44 (0) 121 523 8437